Marlin

NanoLube™

marlinnanolube.com

NANOLUBE™

The Re-engineered Hydrocarbon Molecule is what makes NanoLube™ such an effective friction reducer!

It’s the molecule that makes the difference.

The small size and electrical charge enable it to bond to the metal surface and hold there

under conditions of extreme pressure and temperature.

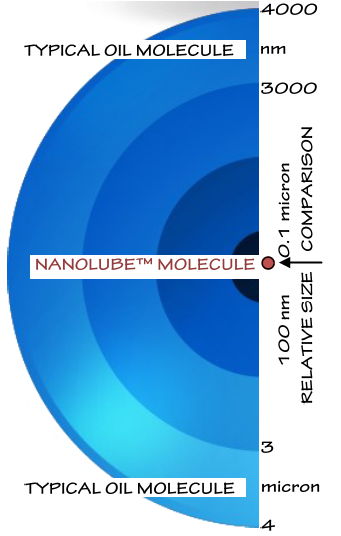

The NanoLube™ structured hydrocarbon is 100nm (nanometer) or (0.100 microns) in size!

Compare this to the average size of oil molecules 3000nm to 4000nm or (3 to 4 microns).

The NanoLube™ molecule holds a negative charge! Most metals become positively charged when heated.

Negatively charged NanoLube™ creates a high-shear-strength layer of lubricant that even advanced oils can’s match.

PREVENTIVE ACTION NanoLube™ metal treatments will provide the greatest gain, short and long term,for preventive action in reducing friction and corrosion. The above Micrograph shows material structures of Molybdenum Disulfide, Graphite, Teflon/PTFE and NanoLube’s treatments. The solid products are 2 to 10 microns in size. NanoLube™ technology is 0.1 micron in size. When NanoLube’s technology is added to an existing lubricant, tiny molecules are carried directly to the friction face. Solid additives (i.e., PTFE, Teflon (a registered trademark of DuPont), Moly, Graphite, etc.) are 2 to 10 microns in size and cannot penetrate as effectively. The monomolecular lubricant technology is about to revolutionize the design and performance of wear components, thanks to the extremely high shear strength of the re-engineered hydrocarbon. Once there, intermolecular force pulls the molecules to the surface where they cluster to fill in any pores or roughness. The remaining areas are covered by a layer just one molecule deep, hence the term monomolecular. The intense shear strength of these microscopic layers provides outstanding smooth running and reduced friction characteristics under the most demanding conditions that even the most advanced engineered lubricants fail to meet.

WARRANTY PROTECTION NanoLube™ metal treatments will NOT void the warranty on your equipment or vehicle. The Magnuson-Moss Warranty Act, US Code; Title 15, Chapter 50, Sections 2301-2312 specifically states that “ a vehicle manufacturer cannot void the warranty on a vehicle due to an after-market part unless they can prove that the after-market part caused or contributed to the failure of the vehicle.” There is nothing in NanoLube™ treatments that can cause any damage when used according to directions.