Marlin NanoLube

™

marlinnanolube.comWARRANTY PROTECTION

NanoLube™metal treatments will NOT void thewarranty on your equipment or vehicle. TheMagnuson-

MossWarranty Act, US Code; Title 15, Chapter 50, Sections 2301-2312 specifically states that “ a vehicle

manufacturer cannot void thewarranty on a vehicle due to an after-market part unless they can prove

that the after-market part caused or contributed to the failure of the vehicle.” There is nothing in

NanoLube™ treatments that can cause any damagewhen used according to directions.

PREVENTIVE ACTION

NanoLube™ metal treatments will provide the greatest gain, short and long term,

for preventive action in reducing friction and corrosion.

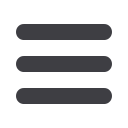

Molybdenum Disulfide Graphite Teflon/PTFE

NanoLube™

The aboveMicrograph showsmaterial structures of MolybdenumDisulfide, Graphite, Teflon/PTFE and

NanoLube’s treatments. The solid products are 2 to 10microns in size. NanoLube™ technology is

0.1micron in size.

WhenNanoLube’s technology is added to an existing lubricant, tinymolecules are carried directly to the

friction face. Solid additives (i.e., PTFE, Teflon (a registered trademark of DuPont), Moly, Graphite, etc.) are

2 to 10microns in size and cannot penetrate as effectively.

Themonomolecular lubricant technology is about to revolutionize the design and performance of wear

components, thanks to the extremely high shear strength of the re-engineered hydrocarbon.

Once there, intermolecular force pulls themolecules to the surfacewhere they cluster to fill in any

pores or roughness. The remaining areas are covered by a layer just one molecule deep,

hence the termmonomolecular.

The intense shear strength of these microscopic layers provides outstanding smooth running

and reduced friction characteristics under the most demanding conditions that even the most

advanced engineered lubricants fail to meet.

THE SAFE SOLUTION

NanoLube™ does NOT contain:

Fluorocarbons; PTFE

Graphite; Molybdenum Disulfide; Sulfides;

Copper; Lead; Silver; nor other metals;

Carbon Tetrachloride; Chlorinated Paraffin; Chlorinated Solvents;

Nor any other harmful solvents

NanoLube™ does NOT break down under pressure nor release toxins

nor combustible fumes. Seals metal pours from moisture.

NanoLube™ products are classified as non-hazardous under EPA and OSHA regulations and

do NOT require any special handling, storage, or disposal procedures other than those used

for standard petroleum products.

As a petroleum derivative, NanoLube™ is able to be removed with typical solvents.